- Chưa có sản phẩm

Dầu bánh răng Mobil Gear 600 XP

Mã sản phẩm Mobil Gear 600 XPDầu hộp số và bánh răng trong động cơ Mobil Gear XP 32, 46, 68, 100, 150, 320, 460, 680

-

0912 532 245

0912 532 245

Mobilgear 600 XP Series

Gear Oil

Product Description

The Mobilgear 600 XP Series are extra high performance gear oils having outstanding extreme pressure characteristics and load-carrying properties, intended for use in all types of enclosed gear drives with circulation or splash lubrication systems. Mobilgear 600 XP Series is designed to stay ahead of the changing needs of gearbox technology. Gearbox technology design trends are towards smaller units with similar power throughput. This increase in power density places increased demands on gear oils. Mobilgear 600 XP Series oils are formulated to meet the stress by providing extra protection for gears, bearings and seals.

Mobilgear 600 XP Series is formulated to protect gear teeth from wear at its earliest stages. Microscopic wear, called micropitting, can lead to significant gear tooth damage. Mobilgear 600 XP Series exceeds the industry requirement for bearing wear protection. In fact, Mobilgear 600 XP Series provides up to 15 times the wear protection as measured by the industry standard FAG FE 8 test. Mobilgear 600 XP Series’ balanced formulation is able to provide maximum wear and corrosion protection while maintaining compatibility with common gearbox seal materials. Mobilgear 600 XP helps to maintain gearbox seal integrity thereby preventing oil leaks and keeping contamination out. By protecting the gears, bearings and seals, Mobilgear 600 XP can improve equipment reliability and increase productivity.

Mobilgear 600 XP Series oils are recommended for industrial spur, helical and bevel enclosed gears with circulation or splash lubrication, operating at bulk oil temperatures up to 100ºC. They are particularly suitable for gear sets working under heavy or shock loads. Mobilgear 600 XP oils also find broad application in marine gearing applications. They may also be used in non-gear applications include highly loaded and slow speed plain and rolling contact bearings.

Features and Benefits

Mobilgear 600 XP Series products are a leading member of the Mobil brand of industrial lubricants that enjoy a reputation for innovation and high performance capability. These mineral-based products are designed to provide high quality industrial gear oils, meeting the latest industry standards and with high versatility to lubricate a broad range of industrial and marine equipment.

Mobilgear 600 XP Series products offer the following features and potential benefits:

| Features | Advantages and Potential Benefits |

|---|---|

| Enhanced gear wear protection from micropitting | Less gear and bearing wear resulting in less unexpected downtime |

| Reduced debris denting from generated wear particles | Up to 22% improvement in bearing life reducing bearing replacement costs and improving productivity |

| Improved bearing wear protection | Improved bearing life resulting in higher productivity |

| Outstanding compatibility with a range of seal materials | Reduced leakage, oil consumption and contamination ingress helping to reduce maintenance, extend gearbox reliability and higher productivity |

| Excellent resistance to oil oxidation and thermal degradation | Helps extend lubricant life with lower lubricant and lubrication costs and reduced scheduled downtime. |

| High resistance to sludge and deposit formation | Cleaner systems and reduced maintenance |

| Wide range of applications | Fewer grades of lubricant required because of wide range of application, leading to lower purchase and storage costs and less danger of using wrong lubricant |

| Optimised resistance to rust and corrosion of steel and corrosion of copper and soft metal alloys | Excellent protection of machine parts, with reduced maintenance and repair costs |

| Resistance to foaming and emulsion formation | Effective lubrication and problem free operation in the presence of water contamination or in equipment prone to oil foaming |

Applications

Mobilgear 600 XP lubricants are used in a wide range of industrial and marine applications, especially spur, helical, bevel and worm gearing. Specific applications include:

- Industrial gearing for conveyers, agitators, dryers, extruders, fans, mixers, presses, pulpers, pumps (including oil well pumps), screens, extruders and other heavy duty applications

- Marine gearing including main propulsion, centrifuges, deck machinery such as winches, windlasses, cranes, turning gears, pumps, elevators and rudder carriers

- Non-gear applications include shaft couplings, screws and heavily loaded plain and rolling contact bearings operating at slow speeds.

- Mobilgear 600 XP 100, 150, 220, 320, 460, and 680 are approved by Siemens AG for use in Flender gearboxes

Specifications and Approvals

| Mobilgear 600 XP meets or exceeds the requirements of: | Mobilgear 600 XP 68 | Mobilgear 600 XP 100 | Mobilgear 600 XP 150 | Mobilgear 600 XP 220 | Mobilgear 600 XP 320 | Mobilgear 600 XP 460 | Mobilgear 600 XP 680 |

|---|---|---|---|---|---|---|---|

| AGMA 9005-E02 | 2 EP | 3 EP | 4 EP | 5 EP | 6 EP | 7 EP | - |

| DIN 51517-3: 2009-06 | X | X | X | X | X | X | X |

| ISO 12925-1 Typ | CKD 68 | CKD 100 | CKD 150 | CKD 220 | CKD 320 | CKC 460 | CKC 680 |

| Mobilgear 600 XP has the following builder approvals: | Mobilgear 600 XP 68 | Mobilgear 600 XP 100 | Mobilgear 600 XP 150 | Mobilgear 600 XP 220 | Mobilgear 600 XP 320 | Mobilgear 600 XP 460 | Mobilgear 600 XP 680 |

|---|---|---|---|---|---|---|---|

| SIEMENS AG Flender gear units, T 7300, Table A-a, Flender Code No. | A17 | A16 | A15 | A14 | A13 | A12 | |

| SIEMENS AG Flender gear units, T 7300, Table E-am, Flender Code No. | E76 | ||||||

| Mueller Weingarten DT 55 005 | CLP 100 | CLP 150 | CLP 220 | CLP 320 | CLP 460 |

Typical Properties

| Mobilgear 600 XP | 68 | 100 | 150 | 220 | 320 | 460 | 680 |

|---|---|---|---|---|---|---|---|

| ISO Viscosity Grade | 68 | 100 | 150 | 220 | 320 | 460 | 680 |

| Viscosity, ASTM D 445 | |||||||

| mm²/s @ 40ºC | 68 | 100 | 150 | 220 | 320 | 460 | 680 |

| mm²/s @ 100ºC | 8.8 | 11.2 | 14.7 | 19.0 | 24.1 | 30.6 | 39.2 |

| Viscosity Index, ASTM D 2270 | 101 | 97 | 97 | 97 | 97 | 96 | 90 |

| Pour Point, ºC, ASTM D 97 | -27 | -24 | -24 | -24 | -24 | -15 | -9 |

| Flash Point, ºC, ASTM D 92 | 230 | 230 | 230 | 240 | 240 | 240 | 285 |

| Density @15.6 ºC, ASTM D 4052, kg/l | 0.88 | 0.88 | 0.89 | 0.89 | 0.90 | 0.90 | 0.91 |

| FZG Micropitting, FVA 54, Fail Stage / Rating | 10 / High | 10 / High | 10 / High | 10 / High | 10 / High | 10 / High | |

| FE 8 wear test, DIN 51819-3, D7,5/80-80. Roller wear, mg | 2 | 2 | 2 | 2 | 2 | 2 | 2 |

| Timken OK Load, ASTM D 2782, lb | 65 | 65 | 65 | 65 | 65 | 65 | 65 |

| 4-Ball EP test, ASTM D 2783, | |||||||

| Weld Load, kg | 200 | 200 | 250 | 250 | 250 | 250 | 250 |

| Load Wear Index, kgf | 47 | 47 | 47 | 48 | 48 | 48 | 48 |

| FZG Scuffing, Fail Stage | |||||||

| A/8.3/90 | 12+ | 12+ | 12+ | 12+ | 12+ | 12+ | 12+ |

| A/16.6/90 | 12+ | 12+ | 12+ | 12+ | 12+ | 12+ | |

| Rust protection, ASTM D 665, Sea Water | Pass | Pass | Pass | Pass | Pass | Pass | Pass |

| Copper Strip Corrosion, ASTM D 130, 3 hrs @ 100ºC | 1B | 1B | 1B | 1B | 1B | 1B | 1B |

| Demulsibility, ASTM D 1401, Time to 3ml emulsion, minutes @ 82ºC | 30 | 30 | 30 | 30 | 30 | 30 | 30 |

| Foam Test, ASTM D 892, Tendency/Stability, ml/ml Sequence 1 | 0/0 | 0/0 | 0/0 | 0/0 | 0/0 | 0/0 | 0/0 |

| Sequence 2 | 30/0 | 30/0 | 30/0 | 30/0 | 30/0 | 30/0 | 30/0 |

Health and Safety

Based on available information, this product is not expected to produce adverse effects on health when used for the intended application, following the recommendations provided in the Material Safety Data Sheet (MSDS). MSDSs are available upon request through your sales contract office, or via the Internet on http://www.exxonmobil.com. This product should not be used for purposes other than its intended use. If disposing of used product, take care to protect the environment.

All trademarks used herein are trademarks or registered trademarks of Exxon Mobil Corporation or one of its subsidiaries unless indicated otherwise.

2-2013

Copyright © 2001-2013 Exxon Mobil Corporation. All rights reserved.

- Mobilgear 600 XP 68

- Mobilgear 600 XP 150

- Mobilgear 600 XP 220

- Mobilgear 600 XP 320

- Mobilgear 600 XP 460

- Mobilgear 600 XP 680

Sản phẩm liên quan

- Molyduval - Germany

- Taihokohzai - Ichinen Japan

- Thiết bị điện chiếu sáng

- WeissSol Japan

- COSMO GREASE JP

- Molykote Dupont

- ExxonMobil

- Brugarolas-Spain

- LUBE - JAPAN

- KLUBER Grease

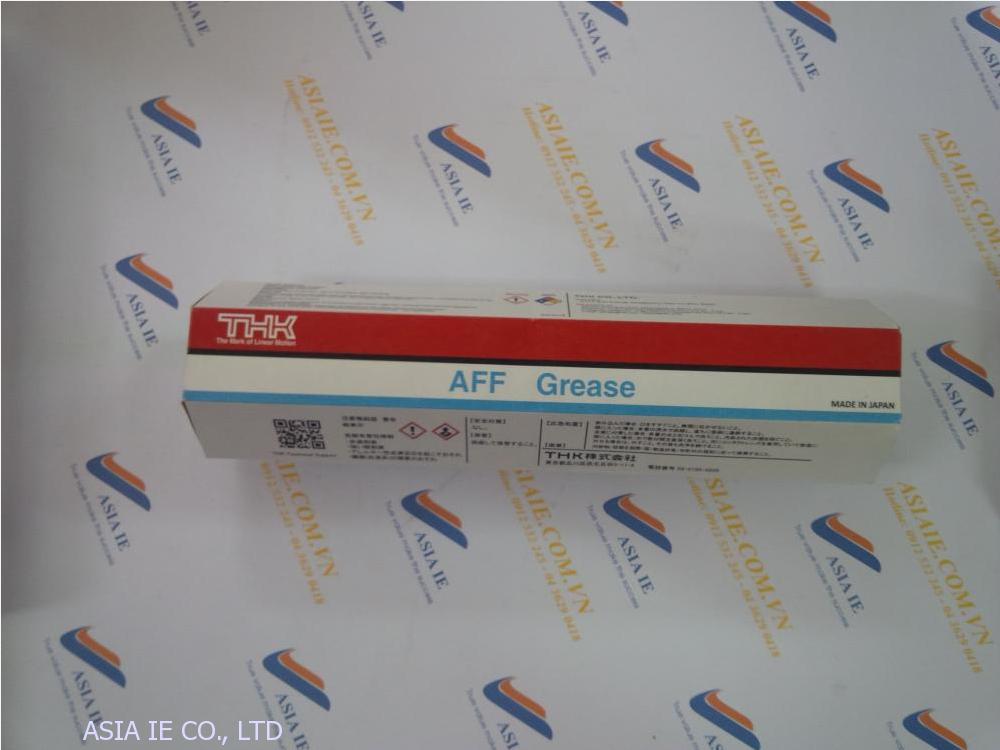

- THK Grease

- JX Nippon Oil

- KYODO YUSHI

- NSK Grease

- Sodick

- Panasonic Grease

- Shell

- IDEMITSU - JAPAN

- Dầu, mỡ đặc biệt cho nhà máy Nhật Bản

- Thiết bị công nghiệp

- Seal Peel- Kanto Japan- hóa chất phủ bảo vệ sản phẩm

- Thiết bị cho dầu mỡ/ Lubrication Equipment

- Hotline 091 253 2245 / 090 465 9928/ 090 456 2977

- Mail tư vấnhiepduong@asiaie.com.vn

- Hôm nay 1127

- Tổng lượt truy cập 4,548,017

Bạn thấy website này thế nào

-

Mã bảo mật:

- Xem thống kê

.jpg)

.jpg)

.jpg)

Bình luận từ Facebook

Phản hồi